Limult Laterite for Road Construction

Laterite is both a soil and a rock type rich in iron and aluminum and is commonly considered to have formed in hot and wet tropical areas. Nearly all laterites are of rusty-red coloration, because of high iron oxide content. They develop by intensive and prolonged weathering of the underlying parent rock. Tropical weathering (laterization) is a prolonged process of chemical weathering which produces a wide variety in the thickness, grade, chemistry and ore mineralogy of the resulting soils. The majority of the land area containing laterites is between the tropics of Cancer and Capricorn.

The term ‘Laterite’ appeared in academic literature over a century ago. Buchanan (1807) first used this term to denote a building material in the mountainous region of Malabar, India (Maignien, 1966). The term ‘Laterite’ could mean brick earth in some local dialects but the name ‘latérite’ got its meaning from a Latin word later, meaning ‘brick’ and so relating solely to the use of these soils in block making (Prescott and Pendleton, 1952 in Gidigasu, 1974). There have been so many arguments,

Characterisation of laterite for road construction

Lateritic soils exist in many places in tropical regions of Africa and America. They are frequently used for road construction. It is important to use them in an optimized way and attempts are made to improve their description and characterization for road applications. Laboratory work done in Brazil, Senegal and France was aimed at including specific properties of laterites in their classification, especially the degradability of their gravelly and sandy fractions due to weathering and compaction during construction works. The paper presents results of laboratory tests, which highlight the importance of particle size reduction due to compaction and its variability. The link between the grain sizes of raw laterites and those of the same laterite after compaction should be further studied, in order to help the road designer in tropical and equatorial countries.

Structure, Composition and Properties of Lateritic Soils

Laterites vary greatly in structure, but can be reduced to the following three structural patterns:

(a) The indurated elements form a continuous, coherent skeleton;

(b) The indurated elements are free concretions or nodules in an earthy matrix;

(c) The indurated elements cement pre-existing materials. These structural patterns exhibit great variability in relation to the shape and size of the elements involved and the degree of induration. The degree of hardness ranges from products that are practically unconsolidated and scarcely coherent to the hardest blocks which can be broken only with a hammer. Induration is an empirical criterion, as it is impossible to give quantitative expressions to any character related to the mechanical properties of the material. The usual definition of induration is a state in which the hard brittle consistency of the medium is not affected by humidity. Induration, which involves the precipitation of goethite in a reticular network, is influenced by composition and the extent of crystallization of the components in the soil: the higher the sesqui oxide content, the greater the induration. In other words, hardness increases as the iron content increases; the hardest laterites are also the least hydrated.

Laterites vary in color, but are usually brightly colored. The shades most frequently encountered are pink, ochre, red and brown; however, some occurrences are mottled and streaked with violet, and others exhibit green marbling. A single sample may exhibit a whole range of colors merging more or less perceptibly into one another in a variety of patterns and forms. Laterites owe their color to iron oxides in various states of hydration and sometimes also to manganese. Their mineralogy generally involves quartz, kaolinite, hematite, goethite, and sometime maghemite. Kaolinite is always present with iron oxides. The physical properties of lateritic soil vary according to the mineralogical composition and particle size distribution of the soil. The granulometry can vary from very fine to gravel according to its origin, thus influencing geotechnical properties such as plasticity and compressive strength. One of the main advantages of lateritic material is that it does not readily swell with water. This makes it an excellent packing material particularly when it is not too sandy.

Improving Lateritic Soils for Construction Purposes

Stabilization processes are very complex because many parameters come into play. The knowledge of soil properties can help to better consider what changes, the economic studies (cost and time), as well as production and construction techniques to use. The simplest process consists of taking soil and drying it in open-air. It is the ―pise technique, rammed earth, adobe, and brick dried in the sun, widely used in the majority of African countries. More elaborate processes can include heat treatment, or mixing soil with ordinary Portland cement, lime, etc.

Limult Group sells quality Laterite for road constructions_ thus providing for the nation. Feel free to visit our store at www.limult.com/shop to see more products that we make available for the people. For further inquiries, call us on +2347052446249.

Limult Survey Plans

A land survey represents pictorially the legal boundaries and dimensions of a surveyed parcel of land. It identifies the type and location of monuments or survey posts set in the ground to define the boundaries of the parcel. Some types of survey plans are subdivision plan, reference plan, posting plan, air space plan or strata plan.

Survey plans are prepared by professional Limult land surveyors for filing in a land title office. Many historical survey plans are available only in hardcopy format.

A plan is a technical and legal document prepared by a registered cadastral surveyor.

A plan is considered current until a new survey has been conducted and registered for the subject lot, and a new title issued. The certificate for each lot in Limult refers to the current survey plan. A plan may be the current plan for some of the lots shown on the plan, but other lots may have been cancelled by a newer plan. This may mean that a current plan of a lot could be from the 1900s, whereas the current plan for a nearby lot may be either newer or older.

A survey plan does not include building location unless the property is a building unit. For more information on buildings, contact the relevant local government.

Survey plans do not contain land contours. A registered surveyor can create these plans for you.

A current plan of a lot may not show easements, leases or covenants as such interests may have been created by a different survey plan.

Reading a survey plan

A survey plan will include bearings, distances and area for all parcels covered by the survey plan. Sometimes the measurements for an individual parcel are not included. This occurs where the dimensions of one parcel are the same as the adjacent lots (e.g. if lots 1 to 20 are all the same size, the dimensions may only be shown on lot 1).

A survey plan does not include the measurements from the kerb to the property boundary.

Depending on when the survey was conducted, the information recorded on the plan may vary.

For example:

- Some older plans may include roman numerals, notes and annotations, or the word 'road' when the road had not been named at the time of survey.

- A survey plan may also include old street names.

- Historical survey plans may include county prefixes and prefix abbreviations.

- Depending on the age of a plan, dimensions may be recorded in a number of formats and you may need to convert from imperial to metric.

Contact us

If you need a survey plans service or you have questions about survey plans, Feel free to visit our store at www.limult.com/shop For further inquiries, call us on +2347052446249.

Limult Plaster Sand

Plaster Sand not only can be used to make plaster but it can also be used in a cement/sand/gravel mix to make concrete. Use Plaster Sand to set pavers, or fill in holes and low spots in your lawn.

Plastering is one of the most ancient building techniques. Evidence indicates that primitive peoples plastered their reed or sapling shelters with mud, thus developing more durable structures and more effective screens against vermin and inclement weather. More lasting and slightly materials in time replaced mud. Some of the earliest plastering extant is of a quality comparable to that used in modern times. The pyramids of Egypt contain plasterwork executed at least 4,000 years ago that is still hard and durable. The principal tools of the plasterer of that time were in design and purpose like those used today. For their finest work the Egyptians used a plaster made from calcined gypsum that is identical to plaster of Paris.

Plaster as a medium of artistic expression waned by the 19th century, when imitation and mechanical reproduction displaced this creative art. However, as a surface material for interior walls and ceilings and to a lesser degree for exterior walls, plaster remains in common use. It facilitates cleanliness and sanitation in building and is a retardant to the spread of fire.

which sand is best for plastering?

Sand is a naturally occurring granular material composed of finely divided rock and mineral particles. It provides the structure of plaster, and the quality of your sand can make the difference between success and failure.

Basically river sand are used for any plastering work. Generally, in any plastering work plasterers are used natural sand, crushed stone sand or crushed gravel sand. Though, there is a grading limit of sand which are used in plastering work. Other types of sand will also work, but it could be more expensive to use.

Limult Group sells quality plaster sand for strong housing construction_ thus providing for the nation. Feel free to visit our store at www.limult.com/shop to see more products that we make available for the people. For further inquiries, call us on +2347052446249.

LIMULT KEROSENE

A REVIEW OF HOUSEHOLD USES AND THEIR HAZARDS IN LOW- AND MIDDLE-INCOME COUNTRIES

Kerosene is a flammable liquid mixture of chemicals that are produced in the distillation of crude oil. To produce kerosene, crude oil is distilled in a distillation tower in a process similar to that used to produce diesel and gasoline. It is a medium weight distillate in the refining process, and can be produced by distilling crude oil (here it is known as straight run kerosene) or by hydrocarbon cracking heavier petroleum (here it is known as cracked kerosene). The chemical composition of kerosene is fairly complex, and it is a complex mixture of paraffins (55.2%), naphthenes (40.9%), and aromatic hydrocarbons (3.9%). Kerosene tends to contain hydrocarbons that have anywhere from 11 to 13 carbons in the chains. Liquid kerosene fuels contain potentially harmful compounds, including hexane and benzene.

Since the mid-19th century, when it replaced the more expensive whale oil as a lighting fuel, kerosene (synonyms: kerosene, paraffin, paraffin oil, fuel oil no. 1, lamp oil) has become a major household, commercial, and industrial fuel. “Kerosene” started as a brand name but was later adopted (with a small “k”) as a general descriptor. In the first half of the 20th century, the prevalence of household kerosene lighting greatly reduced as electrification and availability of gas fuels spread, particularly in developed countries. However, in the developing countries of Africa, Asia, and Latin America, kerosene use for cooking and lighting remains widespread. Globally, an estimated 500 million households still rely on kerosene or other liquid fuels for lighting, corresponding to 7.6 billion liters consumed annually.

Produced originally from coal (“coal oil”), but later from the fractional distillation of petroleum oil, kerosene is a transparent liquid fuel with a mixture of hydrocarbon chains 6 to 16 carbon atoms in length. Although kerosene has numerous commercial and industrial applications (e.g., aviation fuel, general solvent), the focus of this article is on household uses, for cooking, heating, and lighting, in low- and middle-income countries. These lead to the most widespread exposures to kerosene and its combustion products.

Kerosene is commonly used in countries where solid fuels—biomass (wood, agricultural residues, and animal dung) and coal—are major household energy sources, often burned indoors without chimneys or smoke hoods.

Kerosene is sometimes advocated as an alternative cleaner fuel for cooking and is often used for lighting where electricity is not available. Some countries, such as India and Nepal, subsidize its retail price to stabilize in-country prices and make it affordable to the poor. However, there is substantial black market diversion of subsidized kerosene, as it mixes easily with the often more expensive diesel fuel, and it is often sold illegally in surrounding countries that do not subsidize it.

Uses

Kerosene is a major component of aviation fuel, making up more than 60% of the fuel. In addition, it can be used as an oil in central heating systems and can be used as a cleaning agent. Although the use of kerosene in many places has decreased over the years as a result of improved access to electricity and natural gas, it is still used extensively in the developing world for cooking, heating, and lighting. Kerosene cooking is extensive in developing countries, especially among urban populations. Kerosene is often seen as a good alternative to solid fuels, biomass, and coal and thus kerosene lanterns are used in places where access to electricity is not available. It is estimated that globally 500 million households use fuels such as kerosene for lighting.

Health Risks

The use of kerosene as an oil in heaters can be dangerous and because of that it is not used frequently. When operating, kerosene heaters can cause degradation of air quality inside a home while producing toxic and carcinogenic gases. Because of this, kerosene is not actively used in home heating in most developed countries.

In developing countries, the widespread use of kerosene comes with numerous different issues. Hazards of kerosene use include poisoning, fires, and explosions. As well, some kerosene lamps emit fine particulates, carbon monoxide, nitric oxides (NOx), and sulfur dioxide when burned. These by-products may reduce lung function and increase risks of asthma and cancer. Although kerosene is still a safer option in many cases than using solid fuels.

Justifiably, pollution from solid fuels has provoked efforts to find alternative energy sources or ways of burning biomass more cleanly. Least polluting alternatives at the household level are solar power and electricity. Gaseous fuels, which burn with higher combustion efficiency are the cooking fuels of choice in most countries. Biogas made from anaerobic digestion of animal dung is used where conditions are suitable.

Limult Group sells kerosene for your home needs thus providing for the nations. Feel free to visit our store at www.limult.com/shop to see more products that we make available for the people. For further inquiries, call us on +2347052446249.

BRICKS BY SHAPES

In the history of professional construction practices, brick is one of the oldest of all building materials. It is also arguably the most durable since there are brick walls, foundations, pillars, and road surfaces constructed thousands of years ago that are still intact. Today, bricks are most often used for wall construction, especially as an ornamental outer wall surface.

Brick Defined

Officially, the term brick is used to denote a building unit made of shaped clay, but in modern times it is used to refer to any stone- or clay-based building unit that is joined with cementitious mortar when used in construction. Typically, bricks are about 4 wide, 8 inches long, with a variety of thicknesses. Larger stone- or clay-based building units of the type used in foundations are usually called blocks.

How Bricks Are Categorized

There are several ways that brick can be categorized. For example, you can divide brick into the types used for facing (exposed and visible on the exterior of a structure) vs. backing bricks (which are used structurally and are hidden from view). Another means of categorizing brick is according to how they are manufactured: unfired (brick that is air-cured) and fired (brick that is baked in ovens to harden it). Bricks can be also categorized according to their typical use: common bricks or engineering bricks. For purposes of residential construction, it is usually common bricks that are of most interest, since engineering bricks are more often used in civil engineering projects, such as road or bridge construction, or sewers construction.

Bricks can also be categorized according to their shape. Some common shapes include:

- Brick veneers: These bricks are thin and used for surface cladding.

- Airbricks: These bricks contain large holes to circulate air and lessen weight. They are used on suspended floors and cavity walls.

- Perforated bricks: These bricks contain many cylindrical holes drilled throughout the brick. They are very light in weight.

- Bullnose brick: These are bricks moulded with round angles.

- Paving bricks: These bricks contain a good amount of iron. They are used in underfoot paving applications.

- Capping bricks: These bricks are used to cap the tops of freestanding walls.

- Hollow bricks: About one-third of the weight of the normal bricks, these are used mostly in partition walls where load-bearing is not required.

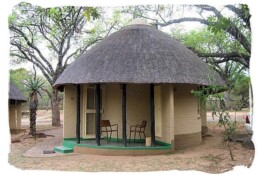

The African hut

A hut is a building of a lower quality than a house (durable, well-built dwelling) but higher quality than a shelter (place of refuge or safety) such as a tent and is used as temporary or seasonal shelter or in primitive societies as a permanent dwelling.

The hut in the 21st century

Although huts still exist in poor, mostly rural Africa, one could safely argue that they are a thing of the past; that these structures have been overtaken by technology and modernization. However, due to their benefits, like natural air conditioning, serenity and tranquility, the hut has found its way into the modern age.

Huts are not only environmentally friendly but also economically sound. A grass-thatched house is cool and when you drink water kept in a pot, it is as cold as water from the fridge,

The re-emergence of the hut stems from the increasing temperature in Africa due to global warming. In order to attract clients, hotels and luxury pubs have adopted a grass-thatched style for their cottages and bars. Huts are very comfortable. This is mainly because of the building materials used. Both clay and grass are good insulators, but they are porous and allow a free flow of air.

It is often very hot during the afternoons in Africa. The hut remains cool and is a welcome resting place. At night, when temperatures fall, the hut retains its daytime temperature, keeping the inhabitants warm.

The question of whether the re-appearance of huts in Africa and beyond is a positive development or a sign of Africans not letting go of their “primitive” past is indeed a question that can be debated.