Acquisition and Sources of Real Estate Investing by Limult

Real estate investing is the involvement of management, purchase, rental, sale, or ownership of a real estate that can be used as profit. Real estate development is the improvement of a specific realty property as part of the strategy in the investment of real estate. This is considered as a real estate sub-specialty. Relative to the other investment kinds, real estate is a form of asset that has fixed liquidity.

Real estate is regarded to be capital intensive and is highly dependent on cash flow. These factors must be well managed and understood otherwise the investor gives himself risks.

One of the main causes for investment to fail in dealing with real estate is because the investor experiences a zero cash flow for quite some time wherein the amount can no longer be sustained; this will result to a forced reselling of the property gone into insolvency.

Acquisition and sources

Acquiring and looking for sources of real estate is not hard although the real estate market in numerous countries are not that efficient or organized compared to other having instruments of liquid investment. Individual properties are not interchangeable and are unique by themselves. This presents one big challenge to investors who want to evaluate investments and price opportunities.

This is one reason why when searching for properties wherein one can invest in, it involves competition and substantial hard work among the investors to be able to purchase properties. This will be variable depending on the availability knowledge.

It will also provides a lot of opportunities for the investors to acquire properties at cheaper prices but poses an increased risk in terms of transaction. Investors of real estate usually use a number of appraisal methods in order to figure out the value of the property before the purchase.

Sources of properties

for investment include:

- Agents of real estate

2. Market listings

3. Private sales

4. Public auction

5. Wholesalers

Sales terms and Price

The moment a property fit for investment is located, the investor will negotiate a sale price and terms with the one selling the property, then after the business talk, the contract for sale will be executed.

In order to be assisted in the process of acquisition, the investors can sometimes employ attorneys or agents having the knowledge about real estate.

This is due to the deal that acquire a real estate posses a lot of complexes which may lead to a very costly deal if executed improperly.

During property acquisition, the investor makes an offer to

buy the reserve of the investor’s right to complete their transaction upon

satisfactorily negotiating with the latter. This reservation money can be

refunded or not and is a sign for the investor’s willingness and seriousness to

purchase the property.

The terms for the offer in real estate investing include

several contingencies that allow the investor sufficient time to complete

diligence and acquire financing before the final purchase. During the

contingency period, the one investing usually reserve the right to abolish the

offer with no attached penalties and accomplish refund on money deposits. Once

the contingencies expired, rescinding usually requires the forfeit of money

deposits and may sometimes leave penalties as well.

That is why, to avoid such penalties, the investor must have

a great deal of understanding and knowledge on the venture that he has to

overcome. Legal advises from people having investing backgrounds will greatly

help to lessen the risk.

Contact us at

+2347052446249 for more information on our redefining industry development

services or visit our store at www.limult.com/shop to see more products

that we make available for the people.

Ceramics Industry by Limult

Industrial ceramics

Ceramics are broadly defined as inorganic, nonmetallic materials that exhibit such useful properties as high strength and hardness, high melting temperatures, chemical inertness, and low thermal and electrical conductivity but that also display brittleness and sensitivity to flaws. Ceramics are used in many industrial applications to support manufacturing within sectors such as metallurgical, chemical, mechanical, and energy production.

Properties that make these materials desirable in these fields are primarily wear and corrosion resistance, hardness, resistance to chemical attack, thermal and electrical insulation, and high-temperature resistance and compressive strength.

Ceramics are used in industrial applications including thermal barrier coatings and thermal insulating textiles, and electrical insulators for machinery components and sensors.

LIMULT GROUP is a manufacturer of the Industrial Precision Advanced Ceramic Parts and Components.

As a ceramic parts manufacturer, we can offer machining or customized full range of precision ceramic parts according to customer requirements.

Contact us at +2347052446249 for more information on our refining industry development services or visit our store at www.limult.com/shop to see more products that we make available for the people.

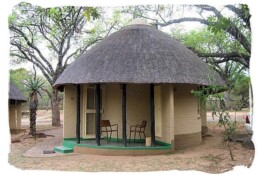

Hut Housing Construction Firm In Lagos State, Nigeria

At Limult, we build the best clean contemporary hut and thatch houses in this state. Visit www.limult.com/shop to learn more

Limult Plaster Sand

Plaster Sand not only can be used to make plaster but it can also be used in a cement/sand/gravel mix to make concrete. Use Plaster Sand to set pavers, or fill in holes and low spots in your lawn.

Plastering is one of the most ancient building techniques. Evidence indicates that primitive peoples plastered their reed or sapling shelters with mud, thus developing more durable structures and more effective screens against vermin and inclement weather. More lasting and slightly materials in time replaced mud. Some of the earliest plastering extant is of a quality comparable to that used in modern times. The pyramids of Egypt contain plasterwork executed at least 4,000 years ago that is still hard and durable. The principal tools of the plasterer of that time were in design and purpose like those used today. For their finest work the Egyptians used a plaster made from calcined gypsum that is identical to plaster of Paris.

Plaster as a medium of artistic expression waned by the 19th century, when imitation and mechanical reproduction displaced this creative art. However, as a surface material for interior walls and ceilings and to a lesser degree for exterior walls, plaster remains in common use. It facilitates cleanliness and sanitation in building and is a retardant to the spread of fire.

which sand is best for plastering?

Sand is a naturally occurring granular material composed of finely divided rock and mineral particles. It provides the structure of plaster, and the quality of your sand can make the difference between success and failure.

Basically river sand are used for any plastering work. Generally, in any plastering work plasterers are used natural sand, crushed stone sand or crushed gravel sand. Though, there is a grading limit of sand which are used in plastering work. Other types of sand will also work, but it could be more expensive to use.

Limult Group sells quality plaster sand for strong housing construction_ thus providing for the nation. Feel free to visit our store at www.limult.com/shop to see more products that we make available for the people. For further inquiries, call us on +2347052446249.

BRICKS BY SHAPES

In the history of professional construction practices, brick is one of the oldest of all building materials. It is also arguably the most durable since there are brick walls, foundations, pillars, and road surfaces constructed thousands of years ago that are still intact. Today, bricks are most often used for wall construction, especially as an ornamental outer wall surface.

Brick Defined

Officially, the term brick is used to denote a building unit made of shaped clay, but in modern times it is used to refer to any stone- or clay-based building unit that is joined with cementitious mortar when used in construction. Typically, bricks are about 4 wide, 8 inches long, with a variety of thicknesses. Larger stone- or clay-based building units of the type used in foundations are usually called blocks.

How Bricks Are Categorized

There are several ways that brick can be categorized. For example, you can divide brick into the types used for facing (exposed and visible on the exterior of a structure) vs. backing bricks (which are used structurally and are hidden from view). Another means of categorizing brick is according to how they are manufactured: unfired (brick that is air-cured) and fired (brick that is baked in ovens to harden it). Bricks can be also categorized according to their typical use: common bricks or engineering bricks. For purposes of residential construction, it is usually common bricks that are of most interest, since engineering bricks are more often used in civil engineering projects, such as road or bridge construction, or sewers construction.

Bricks can also be categorized according to their shape. Some common shapes include:

- Brick veneers: These bricks are thin and used for surface cladding.

- Airbricks: These bricks contain large holes to circulate air and lessen weight. They are used on suspended floors and cavity walls.

- Perforated bricks: These bricks contain many cylindrical holes drilled throughout the brick. They are very light in weight.

- Bullnose brick: These are bricks moulded with round angles.

- Paving bricks: These bricks contain a good amount of iron. They are used in underfoot paving applications.

- Capping bricks: These bricks are used to cap the tops of freestanding walls.

- Hollow bricks: About one-third of the weight of the normal bricks, these are used mostly in partition walls where load-bearing is not required.

The African hut

A hut is a building of a lower quality than a house (durable, well-built dwelling) but higher quality than a shelter (place of refuge or safety) such as a tent and is used as temporary or seasonal shelter or in primitive societies as a permanent dwelling.

The hut in the 21st century

Although huts still exist in poor, mostly rural Africa, one could safely argue that they are a thing of the past; that these structures have been overtaken by technology and modernization. However, due to their benefits, like natural air conditioning, serenity and tranquility, the hut has found its way into the modern age.

Huts are not only environmentally friendly but also economically sound. A grass-thatched house is cool and when you drink water kept in a pot, it is as cold as water from the fridge,

The re-emergence of the hut stems from the increasing temperature in Africa due to global warming. In order to attract clients, hotels and luxury pubs have adopted a grass-thatched style for their cottages and bars. Huts are very comfortable. This is mainly because of the building materials used. Both clay and grass are good insulators, but they are porous and allow a free flow of air.

It is often very hot during the afternoons in Africa. The hut remains cool and is a welcome resting place. At night, when temperatures fall, the hut retains its daytime temperature, keeping the inhabitants warm.

The question of whether the re-appearance of huts in Africa and beyond is a positive development or a sign of Africans not letting go of their “primitive” past is indeed a question that can be debated.